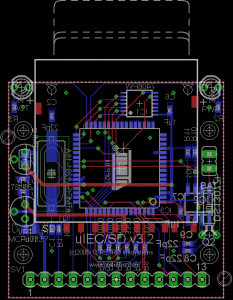

Designing “piggyback” PCBs can prove challenging at times. For example, extending a piggyback PCB outside of the original ICs footprint must contend with physical obstructions (connectors beside the IC, passives like capacitors or resistors sticking out of the original PCB, etc.). Luckily, it’s often easy to print out a 1:1 version of the design on paper, cut to dimensions, and test fit onto the original board. Often, obstructions can be mitigated by switching to SMT components and using a smaller footprint or changing the PCB outline to for around obstacles.

However, less easy to design around are height issues. The best approach involves replacing the original ICs function entirely. Replacement solutions like ROM-el rise little further than the original IC they replace. If the original IC is still needed, but a pass-through of all signals to the original IC is acceptable, the design can utilize a socket both to contain the original IC, and let the pins from the socket function as the header for the piggyback PCB connector to the original socket. This solution typically rises a bit further, but rarely far enough to cause issues.

Designing a piggyback PCB that requires the original IC and must reroute some of the original IC signals forms the worst case. If the original IC height is defined as ‘X’, and we ignore the .8mm to 1.6mm of the PCB, this design still requires a header (‘X’ height), a socket for the original IC (‘X’ height), and the original IC (‘X’ height).

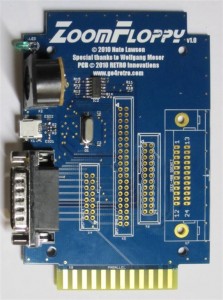

Mind you, most 70’s and 80’s systems designs left lots of room between board or above the original PCB. Thus, 3X height, while potentially looking out of place, will often continue to work. However, as designs became more compact, such luxuries are often unavailable.

The Commodore 1541II disk drive PCB is one such example of the last case. Commodore, in order to reduce overall drive height as much as possible, left little room between the control PCB and the drive mechanism mounted immediately above it. Designing a piggyback board for use in this device is particularly challenging, as there is simply no way to add any height; the drive mechanism won’t rotate the disk if the piggyback board touches it, and you simply cannot relocate the mechanism.

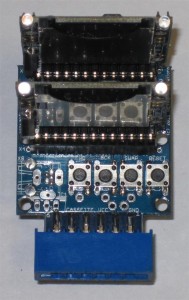

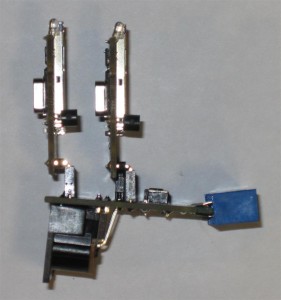

Months ago, I pulled a CMD JiffyDOS ROM out of a 1541II, and was surprised to see an unusual header being used to minimize height. Instead of a normal header, which is simply a batch of double ended pins stuck in a plastic socket, this header used a thin flexible “film” to hold the pins in place, adding no height at all. I had no idea of the source, but a quick request on the CBM Hackers mailing list yielded a source. Vanessa Ezekowitz tracked down the manufacturer (Advanced Interconnections) and the product (Peel-a-Way Removable Carriers).

Of course, this doesn’t solve every problem, but it does offer new hope for designs in height constrained locations. The solution is not cheap (10X the price of a normal IC header), but it can turn an impossible design into a possible product.