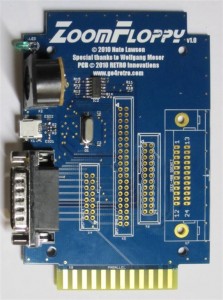

Given continued high demand, existing ZoomFloppy stock sold out mid-May. I’m happy to announce more stock is now available in the store.

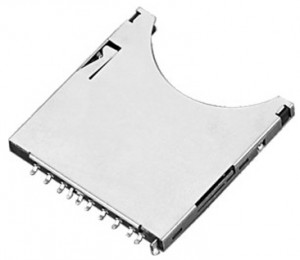

Though I tried for weeks to source a few more of the connectors used on the current uIEC/SD design, the effort proved fruitless. In parallel, I started asking suppliers for other options. As the hope for more old stock dwindled, I decided to source a new connector. I selected a connector that is both less expensive than the older option and can be sourced from multiple companies. This should alleviate my dependence on a single supplier for such a critical component.

I also purchased a stock of Micro SD sockets. The price was right, and I think it’s time I designed something using uSD.

Of course, this decision implies I have to finish the new uIEC/SD board design, spin a new board, and create a new surface mount stencil. Still, the total cost compares favorably to buying old stock SD connectors, even if they were available.

As some may know, IEEE-488 is no longer a preferred global interface standard. I would even go so far as to state it was niche even in its heyday. HP used it as the “Hewlett Packard Interface Bus”, and it was also known as the “General Purpose Interface Bus” (GPIB), as I recall. Still, more names do not increase a standard’s usage.

Now, 30+ years later, it’s becoming quite difficult to find economical sources for IEEE-488 parts. I surmised cables would be expensive, given the number of wires in IEEE-488 cables and the pass through connectors present on many of them. However, I was surprised at the expense for the Centronics 24 pin connector used in the standard. Though 36 pin Centronics (parallel port) connectors are nominal in price, I initially found but a single source offering the 24 pin connectors. Of course, that source offers them for $9.00 a piece.

Recently, I’ve found a more economical source, one that can supply not only the connector, but also the special studs that the standard requires. Though the minimum order is 1000 units, I feel there’s enough demand to justify a bulk purchase. The ZoomFloppy hardware supports the connector already, and future devices should support IEEE-488 as well. Thus, I’ve ordered 1000 connectors, and will add them to the store at the reduced price one they arrive.

I guess I should feel lucky I have been immune to the issue until now, but I have just received word that the newest batch of uIEC/SD units is stalled. The SD connector has been discontinued from 3M, and though I successfully ordered a final reel of them for this production run, the supplier evidently over-committed the remaining units. I’ve spent the last few days attempting to source a comparable option, to no avail. Seeing no other options, I will have to redesign the board to accommodate another SD connector, which means the 200 existing PCBs are now official useless, I’ll need to order a new surface mount stencil (used to apply the solder paste to the PCB before parts are laid onto the board), and the pre-ordered units will be delayed beyond May 31.

It does cause me to wonder why 3M decided to discontinue the offering. It was a economical and very robust connector, so I can’t imagine it was little-used. In any case, it’s no longer available, and I’m left to find a suitable replacement and notify customers of the additional delay.

Often times, classic computer peripheral designs can easily utilize contemporary electronics components without compromise. However, two areas require special care:

As electronics components move to LVTTL (3.3 volt) and below, designs require more buffering to maintain electrical compatibility. Thankfully, such buffering solutions are common and relatively inexpensive. Connectors, on the other hand, bring additional issues.

However, with contemporary connectors moving to serial-based solutions and miniature sizes, larger classic connectors become harder to source and more expensive. This, in turn, greatly drives up product costs and can often price a product out of manufacturing viability. Thus, a while ago, I started dipping my toe into the bulk purchasing pool. With success in hand, I’ve expanded the effort, just recently purchasing 24 and 40 pin headers (for PCB designs that plug into DIP sockets, IEEE-488 jacks (for ZoomFloppy usage), 22/44 .156″ edge connectors (for VIC-20 expansion port usage), and DIN6 jacks (for most IEC-based applications).

While there is inherent risk in such purchases, I feel it’s required to ensure designs can be viably produced and sold.

After I’ve worked on a project for a suitable amount of time, it’s important to let it sit for a few days to allow the design to “mature”, so to speak. Sometimes, nothing changes, but other times, you come up with a great idea that solves lingering concerns with the existing design.

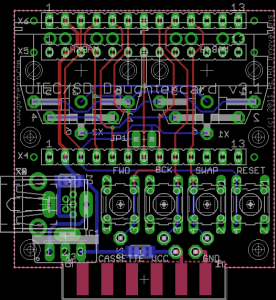

With the uIEC/SD daughtercard design “n the shelf”, an email exchange with customer Ken Page caused me to rethink parts placement. I was unsatisfied with the vertical arrangement of the uIEC/SD main board in the v2 design, but could find no other way to mount the board. However, during the conversation, I came upon the idea of moving the IEC connectors to the bottom of the board. That solved two problems. One, the board needs “standoffs” when plugged into the VIC/64/128 cassette port, or else the board will flex when buttons are pushed or SD cards are inserted. Bottom mounted IEC connectors provide the required height positioning. With them mounted under the unit, I can now offer a horizontal mounting option. In addition, I was able to add 2 more connection pinouts. This means that one can use the daughtercard as a miniature “backplane”, attaching up to 3 uIEC/SD units to a single daughtercard.

I also took the opportunity to put a 7805 voltage regulator pinout on the board and a “barrel plug” wall power adapter option. I do not intend to populate those items, but customers can easily add them.

I realized that no amount of restructuring this design will appeal to everyone. Some people want the smaller board with the single IEC connector. So, I decided to offer both options. The older design is harder the manufacture, so I will price accordingly.

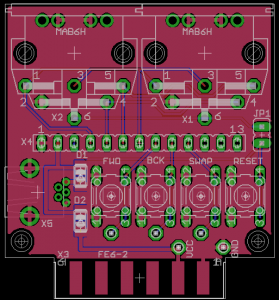

After completing the first revision of the uIEC/SD daughtercard, I grew unsatisfied with with the sole but significant shortcoming. In all applications except the C128DCR usage, the dual IEC connectors would obscure some important port of the host machine. On the VIC/C64/C64C, the connectors would prevent user port usage, while C128/C128D applications would affect video and IEC connector usage. With so many machine types affected, there was little reason to include a cassette port connector, since many of the uses would require a USB power supply.

Removing the cassette port connector would create two issues:

When considering placement options today, I happened upon a nonstandard placement idea that appears to resolve the shortcoming without undue implications.

Since it was important to retain the cassette port connector, this meant IEC jack placement must be directly opposite the cassette port jack. Any other option exhibits the initial issue. However, that left no location for the actual uIEC/SD unit itself. I realized I could orient the drive into a vertical position. Not only does this cleanly resolve the placement issue, this also removes a long standing shortcoming of the previous design. Previously, inserting or removing a card meant holding onto the entire unit so it would not push away from the user. In the new orientation, insertion and removal will require one hand.

The vertical orientation now means VIC-20, C64, C64C, and C128 users can see the top of the unit while looking at their machine. Card access is much easier.

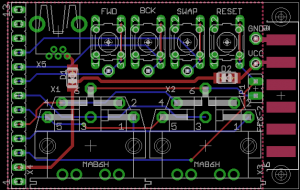

The sole downside: With the unit now perpendicular to the daughtercard plane, enclosure mounting will pose additional challenges. However, I’m much happier with this design over the previous revision:

I appreciate comments and thoughts on this new design. Namely, how do people feel about a vertical drive configuration?

With the next batch of uIEC/SD units, I found both financial and feature-enhancement reasons to redesign the connector daughterboard.

Compared to the earlier daughtercard option, there are some key advantages to the new unit:

The only downside to the new design is the IEC port placement. On the C64/C64C, the IEC ports will interfere with the user port, while they will interfere with IEC and Video ports on the C128/C128D. The C128DCR seems to be least affected. Thus, I am still debating design elements. Comments/Thoughts are greatly appreciated.

Why the change now?

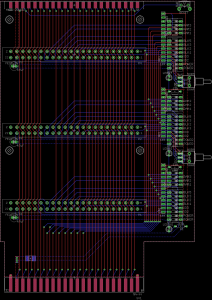

After a lengthy wait, I am finally finishing the VIC version of the X-Pander3 cartridge expansion system. The design is subject to some more changes, but I am starting to source the required cartridge port connectors needed for the design.

The unit shares design elements from the C64 version, but provides maximum flexibility for the VIC-20 owner:

The unit will likely retail for a bit more than the C64 version, mainly due to the additional components and the larger (7.5″x5.0″) PCB size.

Astute viewers will notice an unused switch on each bank. I invite suggestions for use.