For reasons I can only guess, Commodore created it’s IEEE-488 cables in two forms. The first was a standard Centronics 24 to Centronics 24 cable, with each end of the cable offering a passthrough connector (male on the top, female on the bottom). This cable could be used to connect any CBM IEEE-488 peripheral to any other CBM IEEE-488 peripheral, creating a chain of peripherals through a single cable. However, the second, and more important cable was the one that connected the PET or CBM machine to the first peripheral of the chain. And, on one end of this cable, Commodore specified a .156 12/24 female edge connector.

Ordinarily, I’d guess the reason was cost reduction, and that might indeed be the truth, but IEEE-488 cables in general were not cheap, and creating a specific non-standard cable that only Commodore would use seems contrary to a cost reduction move. My next thought was “vendor lock-in”, but if that were the reason, why bother with standard cables anywhere?

There are other theories, of course, and I don’t spend much time considering why these things occur. However, such a design decision makes a real impact today, more than 30 years since the cable debuted. Namely, the non-standard cables are hard to find, and no one produces them anymore (standard IEEE-488 cables are still produced in significant quantities). Since each PET/CBM machine needs exactly one of these cables, they are somewhat important.

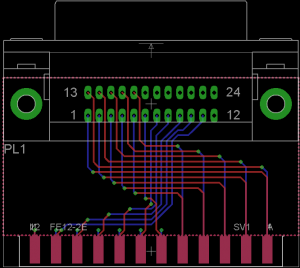

One can always cut a standard cable and wire up a 12/24 connector, but I recently saw a neat idea on a classic computer mailing list that concisely solves the problem: An IEEE-488 connector adapter. The adapter is simplistic to an extreme. One end contains a 12/24 .156″ connector, while the other contains a standard Centronics-24 connector. Coupled with a standard cable, the search for this elusive connection option can be over.

The design seems so simplistic, I’m wondering if there is something else that can be added to the design before I send it off for production. Comments are welcome.